Filter by Catalogue:

Products Found:

LOOKING FOR SOMETHING?

Channel drains, also known as drainage channels, are arguably the most important component of modern drainage systems. They come in various shapes, sizes, and materials. The use of plastic in construction is quite common, and no exceptions are made for channel drains, who have increasingly been manufactured in plastic due to the numerous benefits and flexibility these materials offer.

Drainage channels are generally manufactured in three different types of materials: cement, polymer concrete, and thermoplastic polymer (plastic). Each of these materials has its own benefits for performant surface water drainage. While using robust construction materials and following technical requirements is fundamental for effective rainwater drainage systems, plastic drainage channels present benefits that the other common materials do not.

What Are Plastic Drainage Channels?

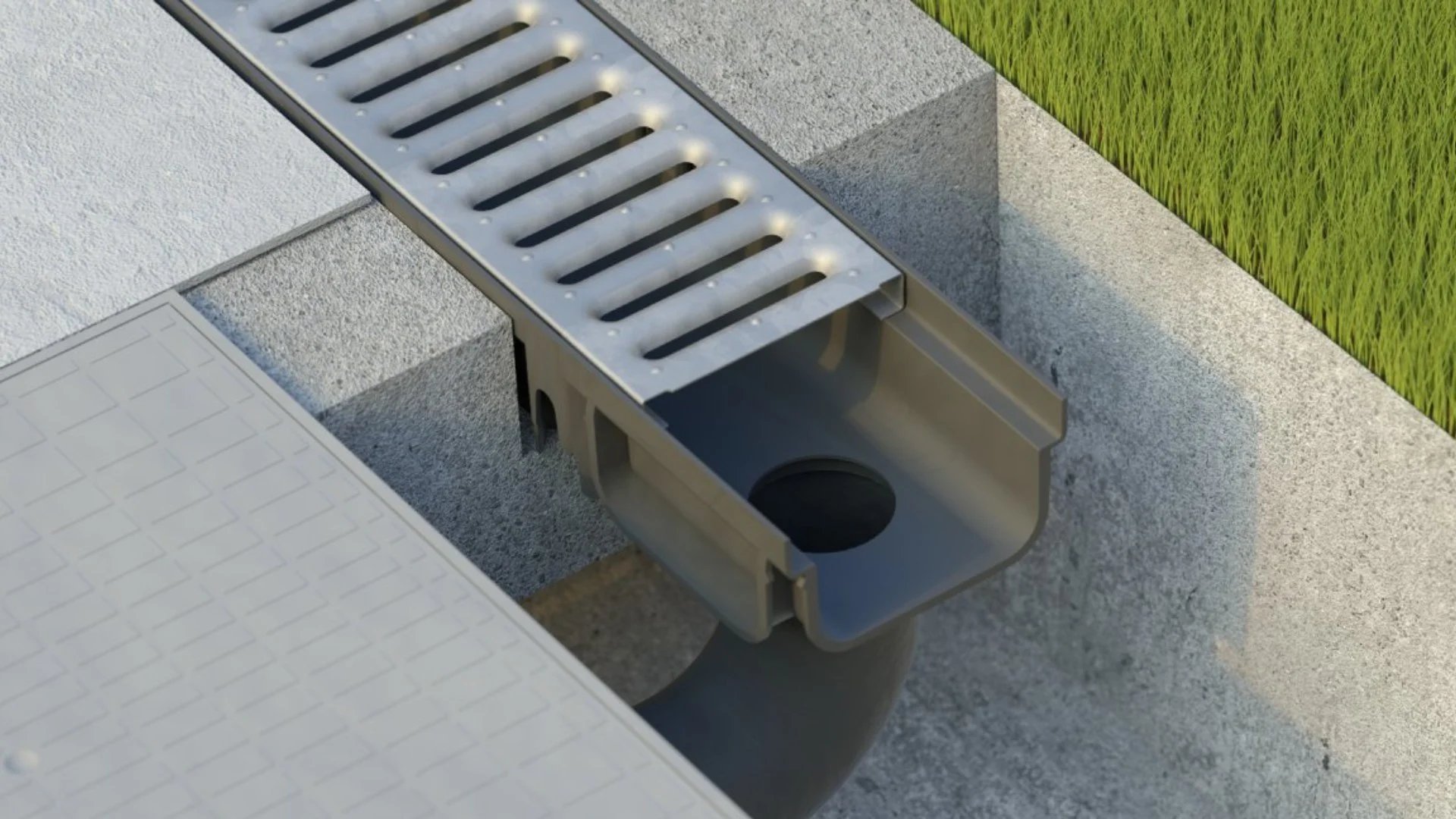

Plastic drainage channels are linear water management systems designed to capture and redirect surface and foul water runoff. Commonly installed in roads, car parks, patios, and industrial yards, they prevent water accumulation and associated damage to structures and pavements.

These systems are typically manufactured in high-density polyethylene (HDPE) or polypropylene (PP) — two thermoplastic polymers known for their lightweight structure, ease of installation, and impressive resistance to chemicals and thermal variations. The combination of durability and adaptability has made plastic drainage channels a trusted solution in both public and private sector construction projects.

What Is a Polymer Drainage Channel?

The term 'polymer drainage channel' refers to drainage systems made from synthetic polymers. It’s important to differentiate between polymer concrete — a composite of mineral aggregates and resin binders — and thermoplastic polymers like HDPE and PP.

Polymer concrete offers impressive compressive strength and is often chosen for high-load industrial sites. However, it’s heavier, less flexible and can be more challenging to handle during installation. Thermoplastic options like HDPE and PP, by contrast, deliver excellent mechanical performance with added benefits:

they are lighter, resistant to corrosion and chemical agents, and can withstand significant temperature fluctuations without structural degradation. This makes thermoplastics particularly suited to projects where ease of handling, speed of installation and long-term durability are key priorities.

Key Benefits of Plastic Channel Drainage Systems

Opting for plastic channel drains brings several tangible advantages over traditional materials like concrete and polymer concrete.

Firstly, they are considerably lighter, reducing transport and handling costs, and simplifying installation procedures — particularly important on projects with limited access or labour constraints. Despite their lightweight structure, these channels maintain remarkable mechanical strength.

Both HDPE and PP offer excellent chemical resistance, withstanding exposure to oils, fuels, salts, and a wide range of industrial effluents without degradation. They are also UV-stable and resistant to thermal shock, performing reliably in environments subject to extreme temperature variations.

One of their most practical features is their self-cleaning inner surface. Thanks to the smooth finish of thermoplastics, debris and sediment are less likely to adhere to the channel walls, promoting higher flow rates and reducing the need for frequent maintenance.

In addition, plastic drainage systems can be equipped with preformed fittings and accessories that accommodate a variety of gratings and covers, making them suitable for everything from pedestrian areas to airports and logistics hubs.

Material Deep Dive: HDPE vs. PP Drainage Channels

Though similar in function, HDPE and PP drainage channels differ slightly in their mechanical properties and suitability for specific applications.

HDPE is known for its toughness and flexibility. It can endure significant temperature variations, is highly resistant to solvents and UV exposure, and offers excellent impact resistance. This makes it an ideal choice for applications subject to harsh weather or demanding operational conditions.

Polypropylene, meanwhile, brags a higher melting point and greater rigidity. It performs well in chemically aggressive environments and is less flexible than HDPE, making it particularly well-suited to projects where dimensional stability and heat resistance are priorities.

Both materials are fully recyclable, aligning with modern sustainable construction practices and contributing to reduced environmental impact through the use of recycled content.

The advantages of HDPE and PP for channel drainage

There are a variety of plastic materials to choose from when manufacturing such building components. Choosing the right types of plastics brings common advantages when designing performant surface water but also foul water drainage systems.

-

Weight: both are relatively lightweight materials, in particular PP, and have a highly beneficial weight/impact resistance ratio. PP is slightly less flexible than HDPE.

-

Ease of installation: they can come equipped with precut fittings and holes, significantly reducing installation times and the needs for additional accessories.

-

Resistant to thermal shocks: they can be laid in environments with significant temperature variations and thrive.

-

Immune to chemical and atmospheric agents: acids, most solvents, alkalis, oils, and petrol will not degrade the materials nor cause system failures.

-

Self-cleaning: the viscosity of the materials, higher than that of the other materials (cement and polymer concrete), means debris and deposits slide off the sides of the channels and limit buildup. This also means that there is a reduced need for maintenance and cleaning. This also translates into higher flow rates, particularly for HDPE.

-

Accessories: they make it possible to install a wide range of gratings and covers, made of various materials, design, and sizes. This is helpful as they can be installed for a wide array of typical uses, from the poolside to the airport runway.

The most important aspect when creating a performant foul water or surface water drainage system is planning (as well as maintenance and drainage channel cleaning). Ask help from a skilled installer when designing rainwater drainage systems. Need more information? Read our basic drainage channel installation guide.

Design & Installation Best Practices for Plastic Drainage Channels

Accurate planning and precise installation can definitely simplify the realisation of the drainage project. Plastic drainage systems should be selected according to their load class — from A15 for pedestrian areas to F900 for heavy-duty applications like airport runways — in compliance with European Standard EN 1433.

When installing, it's critical to maintain a consistent fall (typically 5mm per metre) to ensure effective water flow. Plastic channels often feature preformed outlets and connection points, speeding up assembly and reducing the need for on-site modifications.

Avoid placing freshly laid channels under stress too soon. A 72-hour curing period is recommended when bedding them in concrete to preserve their structural integrity.

Polymer Drainage Channel Applications

One of the greatest strengths of plastic drainage systems lies in their versatility. Thanks to a wide range of grating designs, widths and load classes, they can be installed in a diverse array of environments.

Residential projects often use plastic channels for garden paths, patios and pool surrounds, taking advantage of their discreet appearance and ease of maintenance. Commercial areas, such as retail parks and public squares, benefit from the durability and fast installation of modular plastic systems.

In more demanding environments — like industrial yards, airports, and logistics facilities — high-load plastic drainage channels equipped with appropriate gratings provide reliable water management without compromising safety or longevity.

Environmental & Cost Advantages of Plastic Drainage Channels

Beyond practical benefits, plastic drainage systems deliver important economic and environmental gains. Their lighter weight cuts down on transportation costs and reduces on-site handling times, while preformed accessories lower installation labour requirements.

From an environmental perspective, both HDPE and PP drainage channels can be manufactured using recycled content, supporting circular economy practices within the construction sector. Dakota, for instance, has increased its use of recycled plastics across its product lines, actively contributing to waste reduction and more sustainable building solutions.

Additionally, plastic channels require less maintenance over their service life, delivering long-term cost savings and reducing downtime associated with cleaning and repairs.

Pegasus and Taurus by Dakota

As a drainage supplier, Dakota designs, manufactures, and markets a complete range of drainage supplies and components for drainage solutions - including drainage channels. These are branded 'Taurus' and 'Pegasus'.

These two product lines cover most needs in terms of:

-

Width: from 100 up to 370mm

-

Height: from 50 up to 360mm

-

Length: L from 500 to 1000mm

-

Load classes: combined with our gratings, which are designed for A15 load classes up to F900 (according to European Standard UNI EN 1433:2007)

-

Areas of use: thanks to our wide range of covers and gratings with our channel drains can be combined, Dakota drainage channels can be installed almost anywhere. Our covers and grates are available in plastics, galvanized steel, stainless steel, cast iron, and ductile iron.

-

Resistance to chemicals: especially true for the Taurus line but valid for all, Dakota’s drainage channels guarantee high resistance to more than 200 common chemical and atmospheric agents.

-

Resistance to temperature changes and mechanical stress: because they are manufactured in HDPE and PP, Dakota channel drains, when installed properly, will provide long lasting surface water drainage.

Every year, Dakota commits to using an increasing amounts of recycled plastics. As a leader in the European construction sector, we aim to reduce packaging waste and plastic waste through recycling practices and innovation. This is our responsibility as a building materials supplier.

Read more about how we are reducing plastics and our wider commitment to the environment.